PROFIL

Doing without additives and relying on the specific properties of milk proteins!

Luc Castillo (President of the BBA Scientific Council and R&D Director of SODIAAL-Fromage) gives us an update on this pre-competitive innovation meta-project, led by the Bba consortium. PROFIL stands for Functionalized Milk Protein Assemblies for Innovation in the Dairy Industry. Started in 2014, it cumulates nearly 60 years of research and development, condensed into 6 years!

What was the main objective of this collaborative innovation project?

PROFIL focuses on the properties of serum milk protein assemblies to replace preservative and texturising additives in dairy products. These proteins come from whey. They are present in their native state in milk, and are then, more often than not, expelled with the “whey” during curdling. Led by Joëlle Léonil of INRA UMR STLO, in close collaboration with laboratories from INRA Nantes, BIA, Agrocampus Ouest, IMMM, LUBEM and ONIRIS, this project aims to return these serum proteins to the milk, after having functionalized them by gentle heat treatments, to optimize their properties. It is divided into 5 areas:

- Antifungal properties

- Emulsifying and bulking properties

- Texturising properties

- Vectorising properties

- Innovative route to protein assembly production

What is its innovative character and what are the benefits?

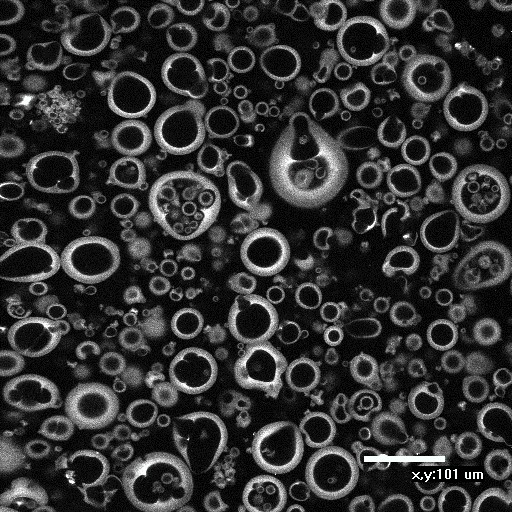

The use of these proteins as preservatives, texturising and vectorising agents is totally innovative. Protein assemblies can take several forms depending on the operational management of the technological processes used: fractals, microgels, fibrillar, mixed. These forms have different properties. Similarly, their size is an important parameter. Innovative tools have been developed to characterise their properties and stability.

These protein assemblies are now being tested in dairy products manufactured on a pilot scale. Thus, thanks to this large-scale collaboration, it will be possible to reduce the use of exogenous additives, while guaranteeing good conservation of dairy products and control of the organoleptic characteristics of the products. This project has given our Western dairy companies a strategic lead: the parliamentary report on food presented last September to the National Assembly plans to reduce the number of authorised additives in the food industry from 338 to 48 by 2025. It will then be decisive to have Clean-label alternatives.

Where do you stand today?

The project is in its last official year. 9 of the 11 theses planned have been defended. These last two theses are applicative and will make it possible to validate the industrial feasibility of these new products, by also validating the organoleptic appreciation of consumers. Numerous fixed-term contracts, internships and internal mobilisation of the scientific teams have contributed to mastering these new tools. The knowledge provided is colossal (about a hundred communications) and many results need to be processed for better appropriation and valorisation.

You have embarked on this collaborative innovation project with several partners: what does innovating in collaborative mode mean to you?

To carry out this ambitious project, partners who are experts in their fields have come together in a consortium of industrialists, Bba. These companies are pooling their resources to go further together, asking themselves the right questions to always be one step ahead.

The human, financial and technical resources involved encourage the partner laboratories to increase their competence in strategic areas. This is the challenge of the Clean Label. Moreover, the tools developed will be usable by all for the future. The pooling of each party’s expertise has made it possible to manage difficulties better and to reach the pilot stages more quickly. These are win-win partnerships. Valorial (formerly the PAO) is in charge of steering and leading the project and is fully playing its role as a facilitator of innovation relevant to this sector.

Fiche technique du projet

- Titre du projet : PROFIL : Functionalized Milk Protein Assemblies for Innovation in the Dairy Industry

- Porteur : Bba (Bretagne Biotechnologies Alimentaires)

- Type de projet : Industrial Precompetitive

- Axe thématique : Functional ingredients

- Date de début : January 2019

- Durée : 72 months

- Coût total du projet : 18,4 M€

- Aide totale : 4,2 M€

- Co-financeurs publics : BRETAGNE REGIONAL COUNCIL, PAYS DE LA LOIRE REGIONAL COUNCIL

- Consortium : Bba, INRA UMR STLO et BIA, ONIRIS, ACO, IMMM, UBO LUBEM

Contact

Joëlle Léonil - INRA - UMR STLO

Coordinatrice scientifique du projet Profil